About us

Specialist for complex precision series production

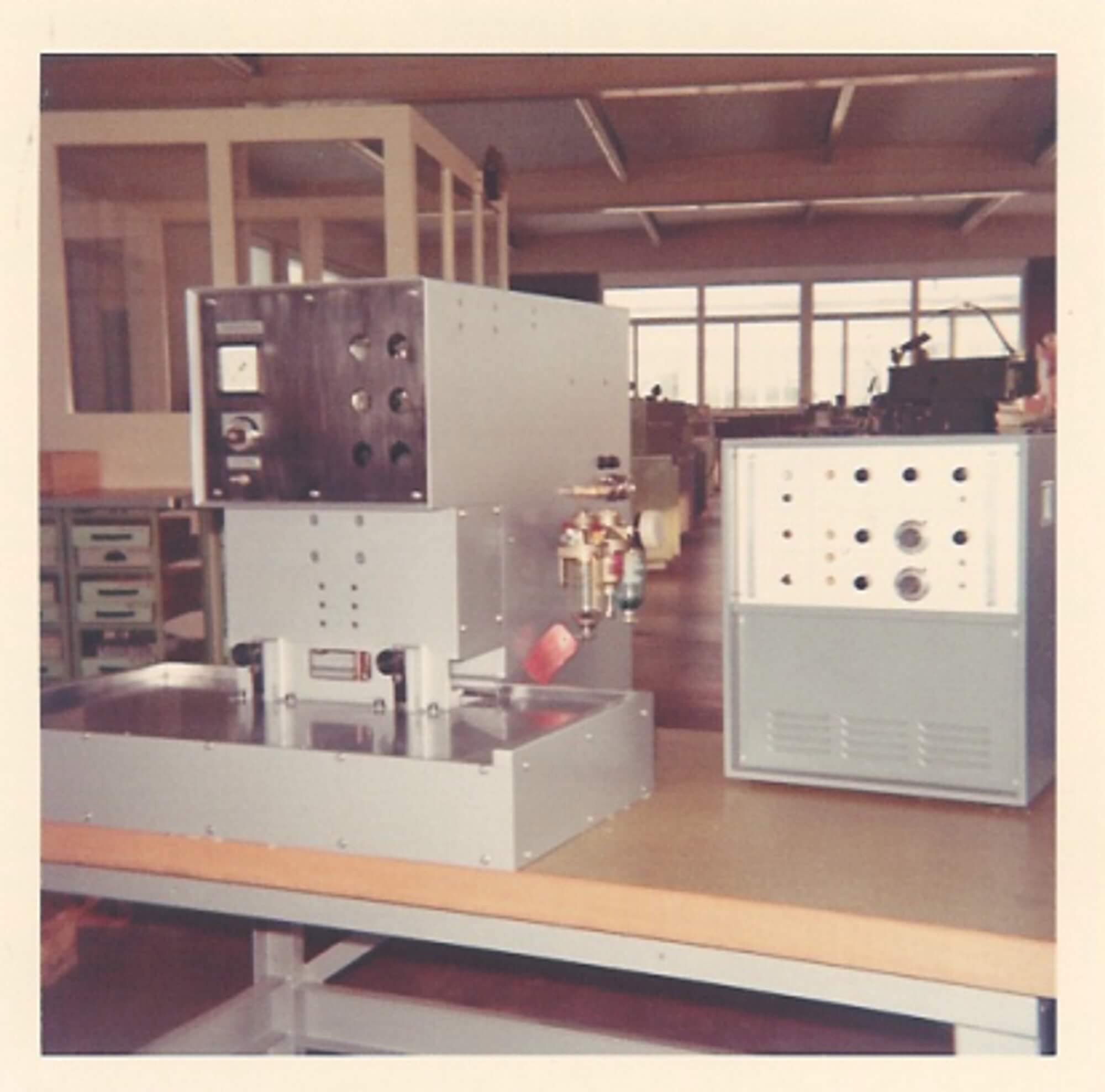

Rau AG has been serving its customers since 1955. Our employees, most of them highly qualified, support you from the planning stage to the ready-to-use components. We manufacture, test and assemble your series articels for you on our own production area.

Core competencies

Our core competencies lie in the series production of complex turning and cubic parts and in system construction with the assembly of series articles with a main part mechanical. Here come the latest machines and production methods in use.

Continuous processes

Our administrative and logistical processes are organised throughout. With our SAP-ERP system, we can cover the most diverse requirements of our customers without compromise.

Know-how

With our many years of experience, but also with our network of efficient partners for additional processing (semi-finished products, coatings) we can completely manufacture the most complex parts for our customers, always in the highest quality, at the right time and at market prices.