Quality assurance

Quality Inspection on a high level

The ISO 9001:2015 certification guarantees perfect quality. By maintaining and ensuring the defined work processes, we are able to meet the high quality requirements of our customers. In the area of production, we have an independent quality engineering department, which ensures that all specifications are adhered to in the process.

- the initial sample inspections, initial piece inspections, intermediate piece inspections, final piece inspections and finally the final quality inspections of the parts.

- Random production checks are carried out according to proven standards.

- specific tests, test plans or documentation are prepared, depending on the customer’s requirements.

- manages and monitors the test equipment of the entire company.

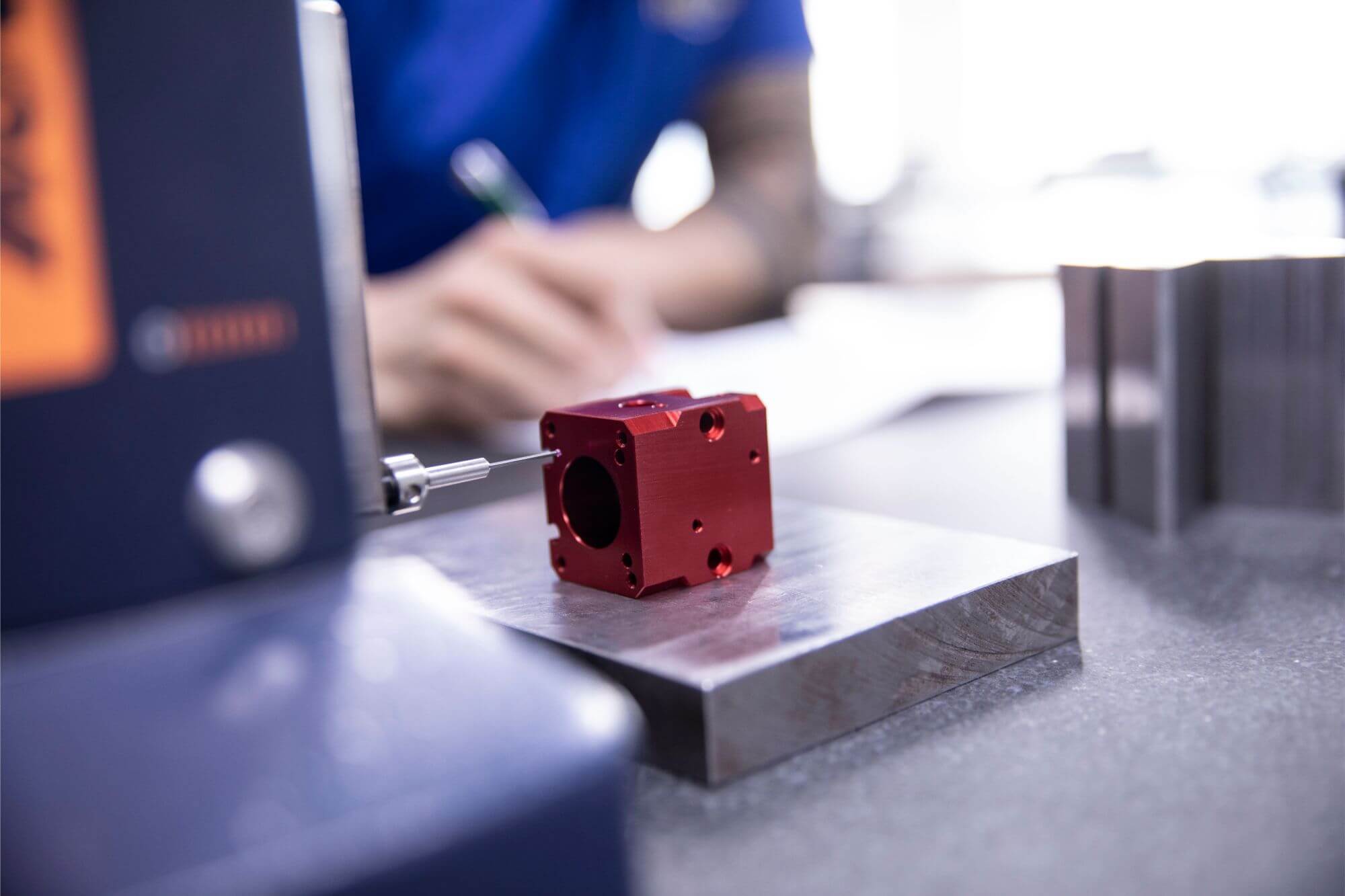

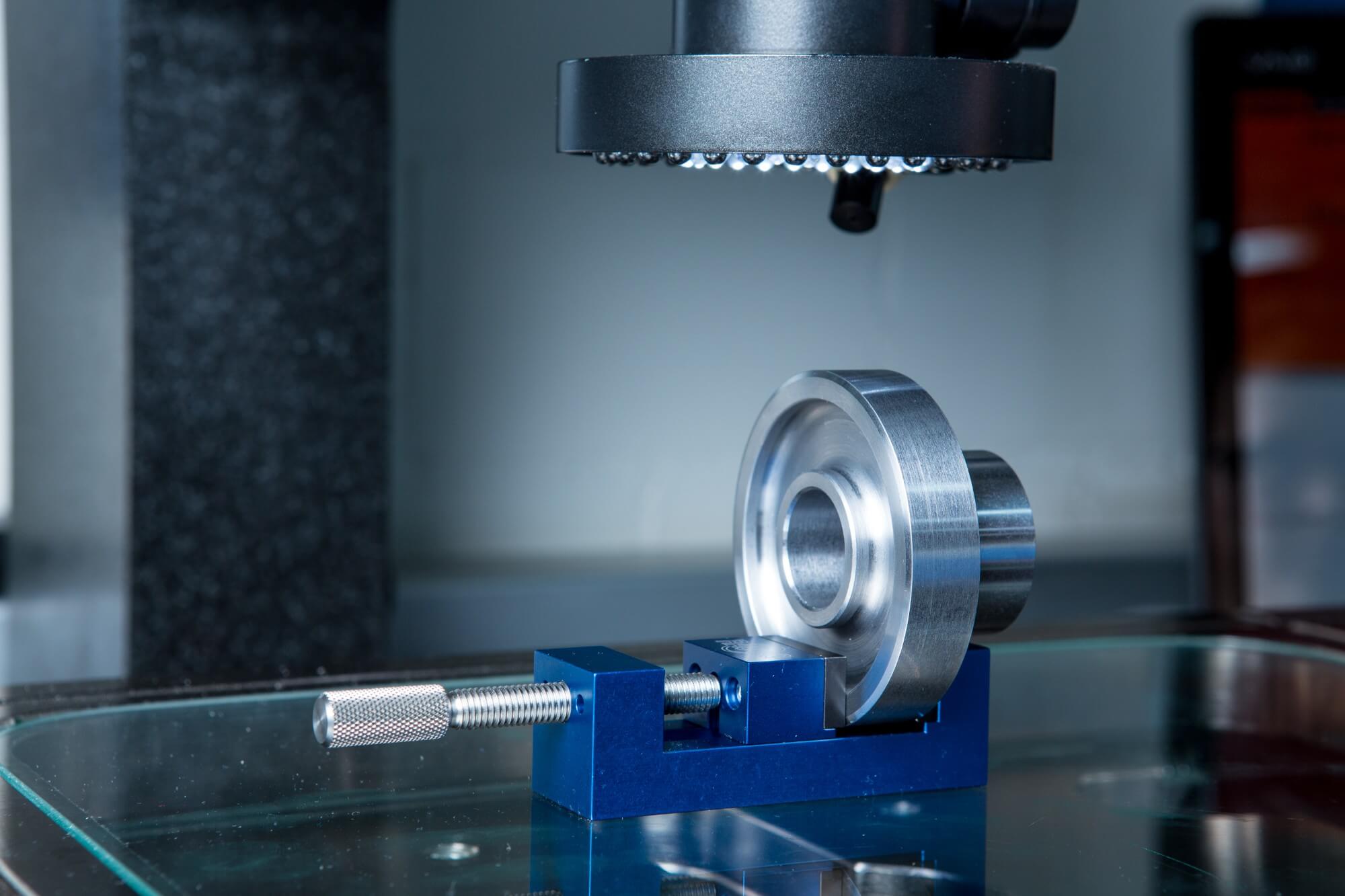

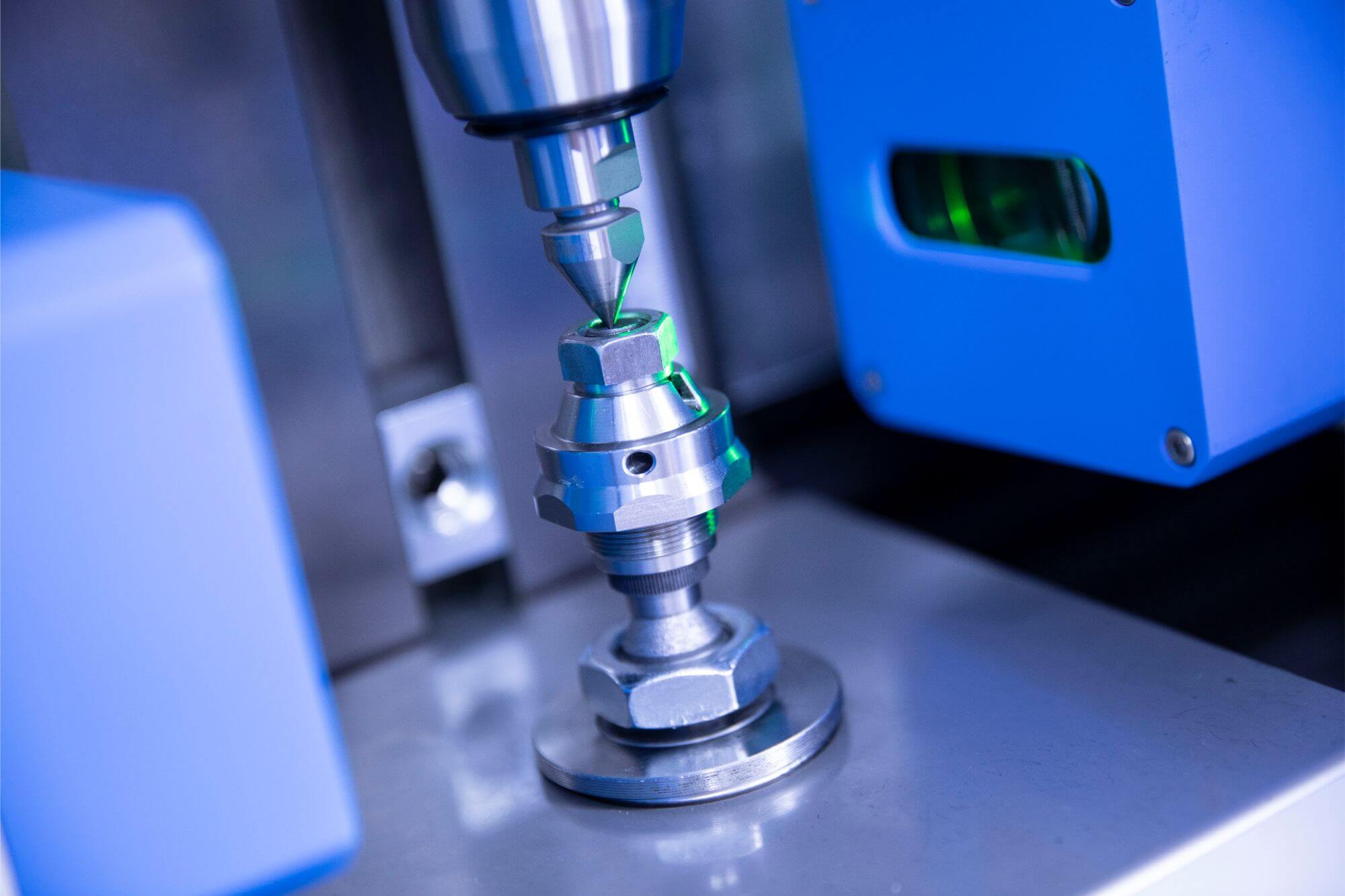

Different quality tests are carried out:

- Coordinate measuring machine Zeiss Contura G with state-of-the-art software

- Optical wave measuring instrument Jenoptik with state-of-the-art software

- Microscopes, roughness measuring instruments

- A variety of handheld measuring instruments (micrometers, micrometer gauges, etc.)

- Height gauges, dial indicators

- A large number of limit plug gauges and gauges

- Most modern software for statistics, test plan preparation and management of measuring equipment

- Software for processing customer data in our measurement processes

The following equipment is available:

Document

Certificate