Production /

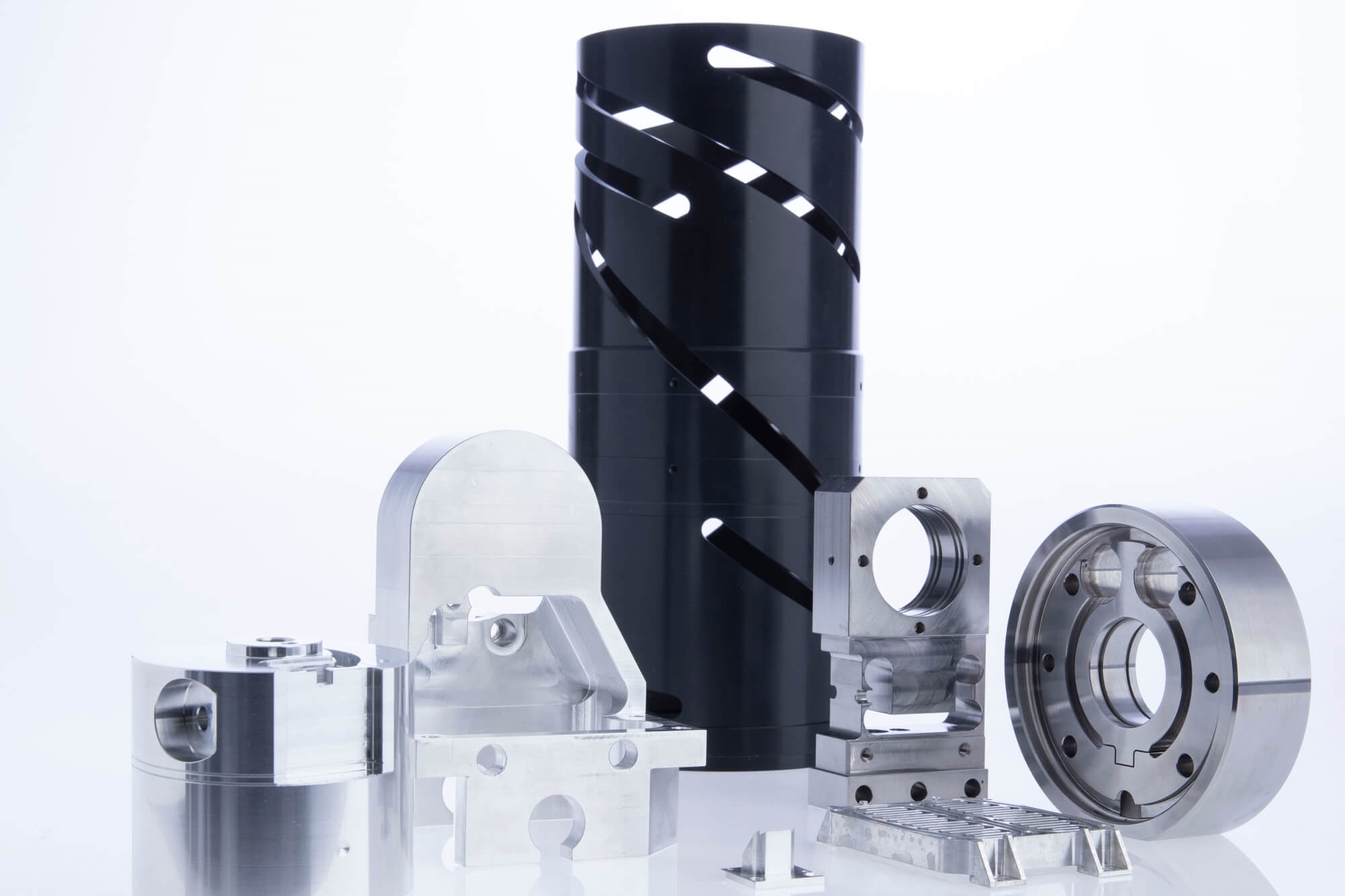

Rotation parts

Picture gallery rotation parts

Two different strategies when turning

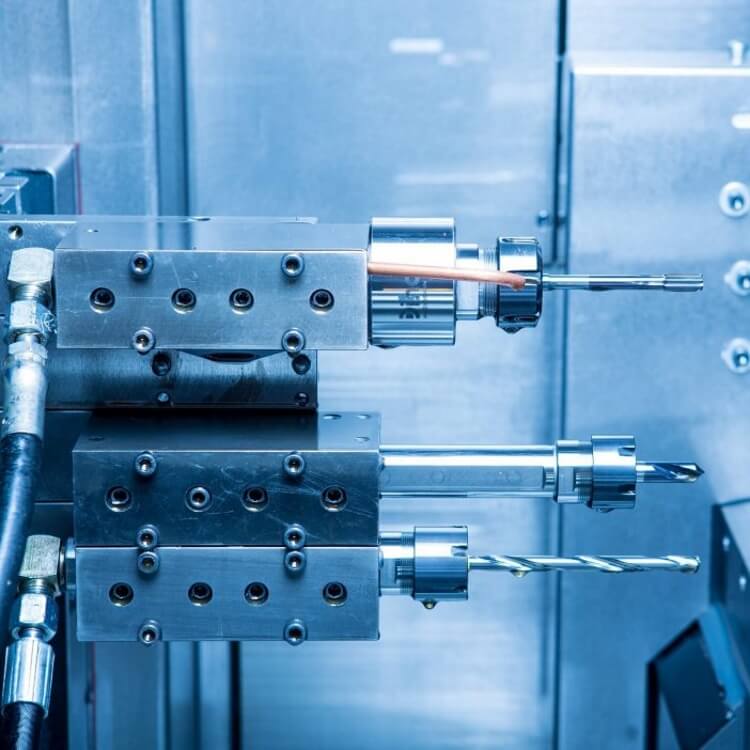

Sliding headstock

- We manufacture small filigree parts on our bar lathes. Here we can produce decolletage parts up to an average of 25mm. Bar loading magazines enable us to manufacture unmanned. These machines have up to 12 axes and up to 4 tools can be used simultaneously. Thanks to high-pressure pumps (120bar) and high-frequency spindles (500001/min), long holes as well as very small holes can be produced without any problems.

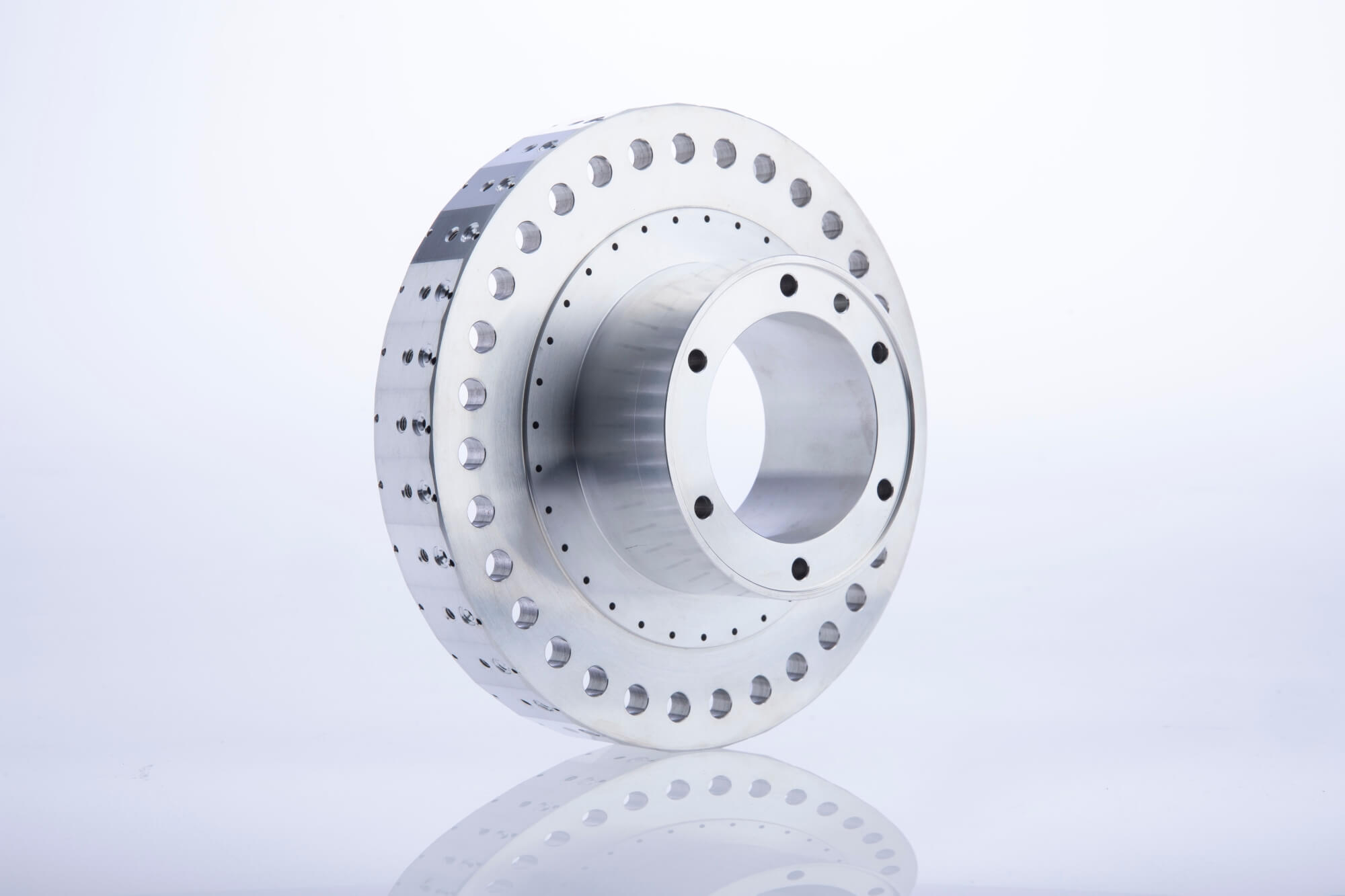

Fixed headstock

- We manufacture complex parts up to a diameter of 80mm from bar stock on our fully monitored turning centres. The machines have up to 3 turrets and 12 axes. Bar loading magazines and handling systems enable us to process shaped parts, blanks and bar material in 24-hour operation.

- Turning centres for larger workpieces up to a diameter of 300mm are equipped with our robot systems. With the help of measuring and monitoring systems a 24-hour complete production can be ensured.

Picture gallery

sample parts